This part of the project had gone way over time. Day 12 was the final Friday of the 3rd working week, with my flights back to France booked for the following Monday bank holiday. The 90.2 lens was complete, and I knew the results, although i'm going to save them for the testing posts on here. With 1 day left I carried on with the intent to finish a copy of the 50mm lens (I had been making 2 simultaneously but with the time constraint I decided to just push hard to get one copy as perfect as possible and leave the remaining parts for next time).

The 50.2'8 lens was a bit more fun to construct compared to the 90.2. There are more parts doing more things, even though there are 3 less elements.

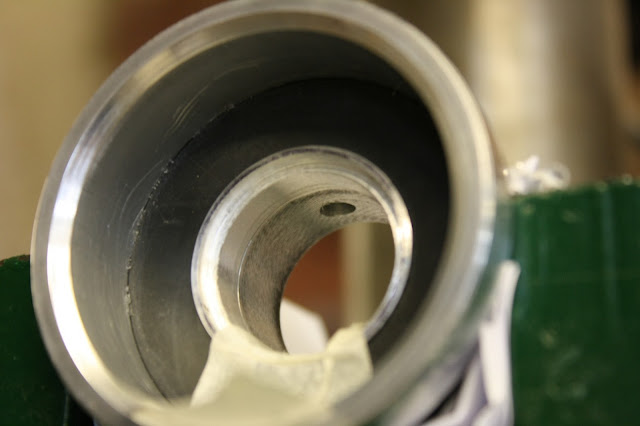

Job 1. Epoxy the fixed parts together. This included the black nylon support block in the centre of the lens (shown above) and the nameplate to the front optic.

Job 2. Sort out split barrel problem.

The rear of the split barrel fitted perfectly, but would fall out of the lens housing when turned upside down. Now there are people wanting to test this lens who are going to be using it on 1000€+ camera bodies, me included with my 5DII, so there was no way I could ignore such a big problem like the split barrel falling out. If it fell out while mounted on the camera it would smash into the mirror (or even bloody worse, the actual sensor!) and do some serious damage. My quick fire solution was to drill a hole through the entire barrels and support material so a retaining pic could be dropped in to keep the inner split barrel in place.

After a bit of drilling and a lot of messing with a steel rod to get it to fit in the hole, the barrel held fine.

Job 3. Clean the split barrel and assemble the lenses into them

Job 4. Assemble all the parts together.

Done.

After an exhausting 3 week period I had two lenses completed. I had spent every day working, including the days when I couldn't come into school (I had to do the coding) and worked into the nights as well to get these lenses made.

I would like to say A HUGE THANK YOU to Rob, Alan, and Garry at Altrincham Grammar School for Boys for supporting me and giving me absolutely invaluable time on their machines. Without their support all of my work would just be theory. I'm pushing the boundaries of both their machines and the limits of feasible fast prototyping, and I really would be stuck without the help, support, and open mindedness of everyone at the school who let me do what I needed to do with the use of their equipment. Thanks guys!

Now I'm back in France, and I have to review what I've done and decide where to go next. I'm going to write up my testing and explain what's gone right and wrong, where things need to be changed, and what I can learn from such an intense period of high pressure prototyping.