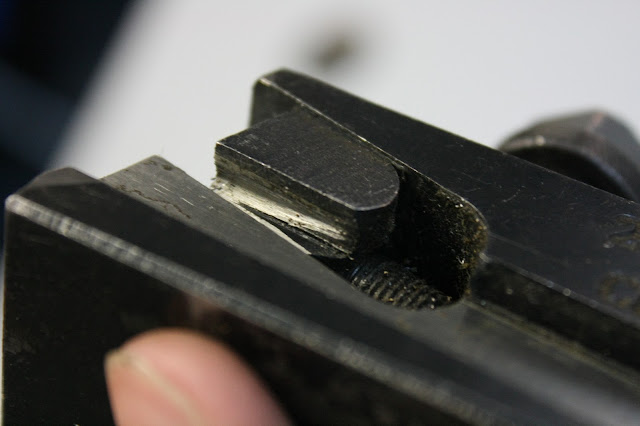

Monday morning, Day 5. After snapping a lens in half on Friday afternoon, and messing up a load of other things, I was praying for just a calm normal day. Infact, that's exactly what I got. Job one when I came in was to solve my parting off problem. There are 4 lathes, 3 manual and one CNC. Of the 3 manual lathes, one is a huge mental lathe which can take over sized pieces, one is a medium metal lathe, and one is a small high speed modeling lathe. I had managed to snap the lens on the medium lathe, so I decided against using that one again. With a lot of experience on the big Harrison metal lathe I decided to try that one. Swapping the tools out of their holders wasn't to tricky, but when i came to put the large tool back into the Harrisons tool holder, it just wouldn't sit flush. Below you can see the huge amount of wear on the top of the housing. This was pushing the tool off the face of the holder. This isn't good for me, I don't trust it, so after faffing about for a bit I decided to ditch the Harrison and use the modelling lathe.

I hadn't wanted to use this lathe as it was brand new this year and still had all it's tools locked into place as it was when it was delivered. I didn't want to be the one to retool it and have to reset the heights for the first time. But in the end thats what happened, and it worked out really well. The modelling lathe has a spindle speed control knob which can be adjusted live as the machine is running. This is an advantage over the other machines as they have to be stopped and regeared. Thanks to this feature, I was able to start slow and speed up the spindle as my tool got closer to the centre point, helping to give a constant material cutting speed (a slow speed at the outside gives the same travel as a faster speed near the inside). With lots of lubricant also, I fed it very slow and eventually got the optic cut off.

After polishing on flat papers and then the buffing wheel the optic became clear. Something worried me slightly. I could see the lens surface wasn't a perfect radii. It undulated in and out slightly (by slightly i'm talking 0.01's of a mm) but enough to make strange distortions. When focusing through the lens there was a softspot in the centre. This is a worrying sign which would later form part of my conclusions. At the time, I thought it could be sorted out with repolising before assembly.

After that it was a case of doing it again... and again... and again. There are 4 plano convex parts to the 90.2 lens, so it was all the same process just with different DXF profiles.

With all these parts looking similar I made sure I indexed each one and put it in a labelled envelope ready for final polishing and assembly.

With the 4 lenses being cut quickly, I had just enough time at the end of the day to cut the outter barrel for the 90.2 lens. It's a long barrel compared to the 50. I sliced a chunk off on the auto-hack saw and parted it to length on the lathe, and that was that for the day!